Brake failure is a serious safety concern. Brake pad wear indicators are your first line of defense against this potentially dangerous situation. These small but vital components act as an early warning system, alerting you when your brake pads are nearing the end of their lifespan. This lets you address the issue proactively. This can save you money on repairs and, more importantly, prevent accidents.

Brake pad wear indicators are essential for optimal braking performance. They provide a crucial safety net, especially during emergencies. Ignoring these warnings can significantly reduce stopping power and increase the risk of accidents.

Driving with worn brake pads can also damage other brake system components, like the rotors. This can lead to more extensive and expensive repairs.

Early detection of brake pad wear is key to maximizing the lifespan of your braking system. Think of it like your car’s “check engine” light. It signals a need for attention to prevent a larger problem.

Similarly, brake pad wear indicators give you time to schedule brake service. This prevents further damage and ensures optimal stopping power. Catching wear early can prevent damage to the rotors, which are expensive to replace.

The importance of these safety components is clear in their market value. The global market was valued at approximately USD 1.2 billion in 2023. It’s projected to reach USD 2.8 billion by 2033. This growth underscores increasing awareness of brake safety and timely maintenance. Find more statistics here: Learn more about the brake pad wear indicator market

Wear indicators contribute significantly to vehicle safety and performance by providing timely alerts for brake pad replacement. This proactive approach helps prevent accidents and ensures reliable braking. This protects your vehicle investment by avoiding costly repairs from neglected maintenance. A well-maintained brake system contributes to your car’s overall value and longevity.

Brake pad wear indicators are vital for your vehicle’s safety, letting you know when it’s time for new brake pads. There are several types of indicators, each with pros and cons. Knowing the differences can help you maintain your vehicle and ensure optimal braking performance.

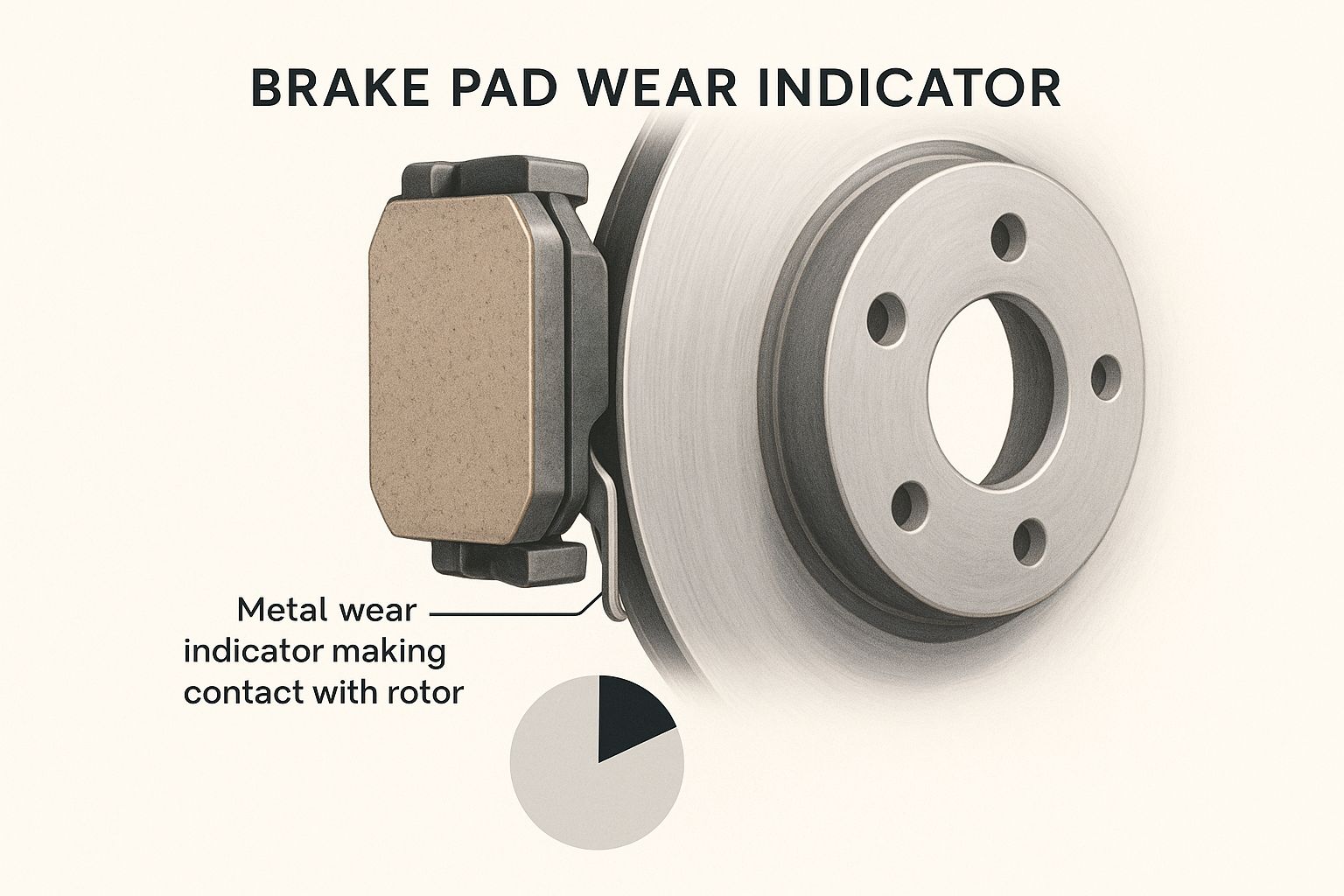

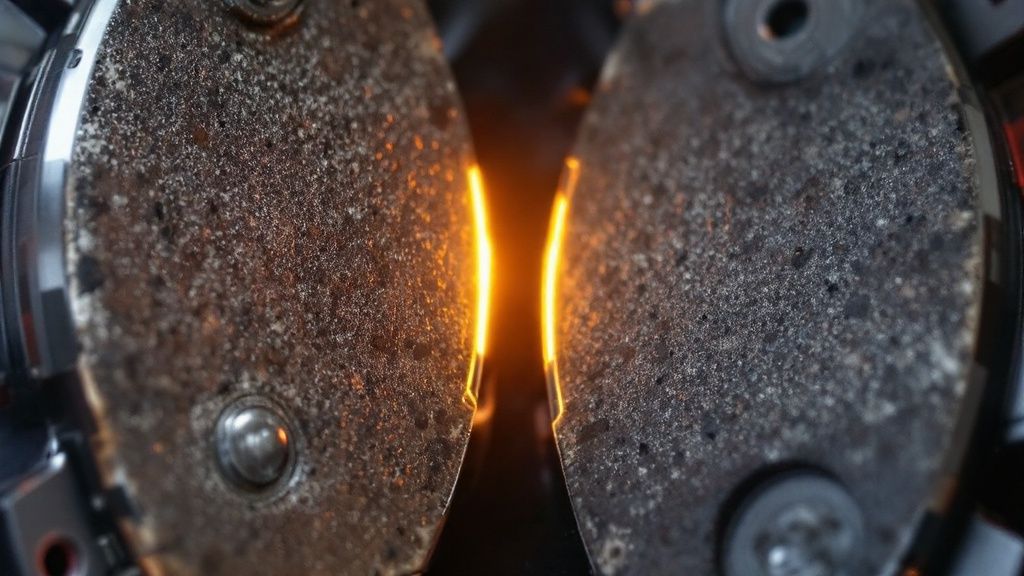

The most common type is the mechanical wear indicator. A small metal tab is attached to the brake pad. As the pad wears, the tab eventually touches the brake rotor. This contact creates a high-pitched squeal, warning you that the brake pads are wearing thin. This noticeable sound prompts you to get your brakes serviced.

This image shows how the metal indicator contacts the rotor as the pad thins, creating the squealing sound. This simple, effective design is common in many vehicles because it’s reliable and affordable.

More advanced vehicles often use electronic wear indicators. Sensors inside the brake pad assembly track pad thickness. When the pads wear down to a certain point, a warning light appears on your dashboard. This visual cue gives you a more precise measurement of brake pad wear than the mechanical squeal. Some luxury vehicles even estimate the remaining brake pad life.

Electronic indicators can also work with other vehicle systems, like Advanced Driver-Assistance Systems (ADAS). This allows the vehicle to adjust braking based on pad condition, increasing safety. The brake wear indicator market is expected to reach about USD 1.25 billion by 2032, with a CAGR of roughly 3.9%. This growth reflects the increasing use of advanced brake monitoring, especially where safety standards are strict. Learn more about market trends: Explore this topic further.

Besides factory-installed systems, there are aftermarket brake pad wear indicators. These can include replacement mechanical indicators or add-on electronic systems. Aftermarket options give you choices if you want to upgrade your current system or add indicators to an older vehicle. Choosing quality brands and ensuring correct installation are key for reliable performance.

To help you better understand the different types of brake pad wear indicators, let’s look at a comparison table:

Comparison of Brake Pad Wear Indicator Types

This table compares the different types of brake pad wear indicators, their features, advantages, and limitations.

| Indicator Type | How It Works | Typical Vehicles | Advantages | Limitations |

|---|---|---|---|---|

| Mechanical | Metal tab contacts rotor creating a squealing sound | Most common type, found in many standard vehicles | Simple, reliable, cost-effective | Less precise, only alerts when pads are very worn |

| Electronic | Sensors monitor pad thickness and trigger a dashboard light | Newer, more sophisticated vehicles, often luxury models | Precise, can integrate with other vehicle systems, may display remaining pad life | More expensive, requires specialized diagnostic tools |

| Aftermarket | Varies depending on the system, can be mechanical or electronic | Vehicles without factory-installed indicators or those seeking upgrades | Offers flexibility and customization options | Requires careful selection and proper installation |

This table highlights the differences between each indicator type, helping you choose the best option for your vehicle and budget. Knowing these options empowers you to make informed decisions about brake maintenance during your next service appointment.

That mysterious squealing when you brake isn’t just annoying; it’s a vital communication from your vehicle. Understanding these signals is key to maintaining your safety and the longevity of your brake system. Let’s explore how your car tells you it’s time for a brake service.

The most common warning sign is a high-pitched squeal or screech when you apply the brakes. This distinct sound originates from mechanical wear indicators, small metal tabs within the brake pad. As the pad wears, the tab contacts the rotor, creating the squeal. Think of it as a small bell alerting you that your brake pads are nearing their limit and need immediate attention.

Many modern vehicles employ electronic wear sensors within the brake assembly. These sensors monitor pad thickness and trigger a dashboard warning light when the pads wear thin. This visual cue offers a more precise measurement of brake pad wear than the audible squeal of mechanical indicators. Electronic sensors often integrate with other vehicle systems, enhancing overall safety.

While squealing and warning lights are primary indicators, other signs can point to worn brake pads. A vibrating or pulsating brake pedal might indicate uneven pad wear or warped rotors. A burning smell after braking suggests overheating due to excessive friction. Never ignore these less obvious signals, as they could indicate serious brake problems.

You can visually inspect your brake pads by looking through the wheel spokes to gauge the pad thickness. If the pads appear thin – less than a quarter-inch of material – it’s time for a replacement. Combining this simple check with awareness of other warning signals allows you to address brake wear proactively. At Kwik Kar of Mesquite, our ASE-certified technicians use advanced diagnostic equipment for accurate brake system assessments. Schedule an appointment today to keep your brakes in top condition. We offer a 24-month/24,000-mile warranty on all repairs, providing peace of mind.

Sometimes, unusual noises or slight braking performance changes aren’t definitive signs of wear. These could stem from various factors like environmental conditions or temporary debris. However, if you’re unsure, err on the side of caution. Bring your vehicle to Kwik Kar for a professional inspection. Our expert technicians can diagnose the cause and provide the right solution. Kwik Kar offers convenient and reliable service, including a comfortable waiting area with complimentary coffee and WiFi. We also have Ladies Day every Wednesday and special discounts for military, first responders, and healthcare workers.

Beyond the telltale squeal, today’s brake pad wear indicators represent a significant advancement in automotive safety. These components are carefully engineered, from material selection to their precise placement within the brake assembly. Let’s explore the details behind these critical safety features.

Brake pad wear indicators are more than just simple pieces of metal. Mechanical indicators, typically crafted from steel, are designed to endure high temperatures and the constant friction of braking. Their precise placement ensures consistent, reliable warnings across various driving conditions. This meticulous design ensures drivers receive timely alerts about their brake pad’s condition. Understanding key performance indicators is helpful for recognizing warning signs in other areas too. More information on relevant metrics can be found by exploring Customer Service Performance Indicators.

Electronic sensors represent a more advanced approach to brake pad monitoring. These sensors utilize sophisticated materials and circuitry embedded directly within the brake pad material. This integration allows them to communicate with your vehicle’s onboard computer, providing real-time data on pad thickness and projected lifespan.

Electronic brake pad wear indicators transmit data directly to the vehicle’s computer system. When the pads reach a predetermined wear level, a warning light illuminates on your dashboard. Some advanced systems go further, estimating remaining pad life based on individual driving habits and braking frequency. This predictive capability allows for proactive maintenance, reducing the risk of unexpected brake failures.

Brake wear indicators undergo rigorous testing to guarantee their performance under a wide range of conditions. Manufacturers subject these components to extreme temperatures, simulating everything from freezing winters to scorching desert heat. They also replicate diverse driving scenarios, such as aggressive braking and steep mountain descents. This comprehensive testing process ensures dependable, accurate wear indication regardless of driving style or environment.

To better understand the progression of this technology, let’s take a look at the following table. It outlines the key developments in brake wear indicator systems, from basic mechanical designs to the advanced electronic systems we see today.

| Era | Technology Type | Key Features | Implementation | Effectiveness |

|---|---|---|---|---|

| Early Years | Mechanical | Audible squeal when pad wears down | Metal tab contacting the rotor | Simple, but less precise |

| Modern | Electronic | Dashboard warning light, pad life estimation | Embedded sensors communicating with the vehicle | Precise, proactive alerts |

| Future | Predictive | AI-powered predictions, personalized warnings | Integration with ADAS and connected car systems | Enhanced safety and efficiency |

As you can see, brake wear indicator technology has evolved significantly, offering drivers more precise and proactive alerts. The future of this technology promises even greater advancements in safety and efficiency.

Your brake pad wear indicators, like any other part of your car, need regular attention to ensure they’re working correctly. Maintaining these vital safety features involves routine checks, proper cleaning, and understanding how your driving style and the environment can impact their effectiveness. This knowledge will help you keep your brake indicator system in top shape throughout your vehicle’s lifespan.

Experienced mechanics follow specific procedures to evaluate the health of your brake pad wear indicators. For mechanical indicators, this means visually inspecting the metal tabs for any signs of damage or excessive wear. This simple check can prevent overlooking a critical safety component. They also listen for the characteristic squeal when you apply the brakes, which confirms the indicators are functioning.

For electronic systems, technicians use diagnostic tools to check sensor readings and ensure they’re communicating correctly with the vehicle’s computer. This confirms the system is accurately tracking pad thickness and triggering warnings as designed. Kwik Kar of Mesquite’s ASE-certified technicians can perform a professional brake inspection to assess the condition of your wear indicators.

Electronic brake pad wear sensors can be affected by dirt, debris, and corrosion, which can interfere with their operation. Cleaning them properly involves carefully removing any buildup around the sensor. You can usually do this with brake cleaner and a soft brush. Avoid using harsh chemicals or abrasive materials.

Using a wire brush, for example, could scratch the sensor surface. This can cause inaccurate readings or lead to premature sensor failure.

Correct installation of both mechanical and electronic wear indicators is crucial. A common mistake with mechanical indicators is incorrect tab placement. This can lead to premature or delayed squealing, giving you inaccurate information about pad wear. For instance, a misaligned tab might not make contact with the rotor at the right time, delaying warnings and potentially damaging the brakes.

For electronic sensors, a common problem is damage during brake pad replacement. This can sever the sensor wire or damage its connector. If this happens, the sensor won’t communicate with the vehicle’s computer. You won’t get a warning light, potentially creating a dangerous driving situation.

Different car manufacturers use various types of brake pad wear indicators. BMW, known for its advanced engineering, often uses complex electronic systems integrated with other vehicle functions. Toyota, known for its dependability, usually uses simpler, more durable mechanical indicators. Understanding the specific system in your vehicle and its maintenance needs is essential for keeping it working effectively.

Your driving habits directly affect brake pad wear and how often your wear indicators activate. Frequent hard braking creates more heat and friction, wearing down your pads faster. This means aggressive drivers may hear the squeal of mechanical indicators or see the warning light of electronic systems more frequently.

Environmental factors, such as road salt and extreme temperatures, can also affect how well your indicators perform. Road salt can speed up corrosion, especially on electronic sensors, sometimes leading to false warnings. Extreme cold can reduce sensor sensitivity, while excessive heat can cause premature wear.

If you hear unusual brake noises or see warning lights, but your brake pads seem okay, several steps can help you figure out the problem. Check for any debris caught between the pad and rotor. This can sometimes sound like a worn mechanical indicator. Also, inspect the wiring and connectors of electronic sensors for any damage or corrosion.

If you’re unsure what’s causing the problem, consult a qualified mechanic. Kwik Kar of Mesquite offers expert diagnostics and convenient appointment scheduling for any brake system concerns.

The future of brake safety is rapidly advancing. Forget simple squeals and dashboard lights; new technologies are transforming how we monitor brake pad wear, offering improved safety and convenience. These systems move beyond basic alerts, providing drivers with detailed information and greater control.

Imagine receiving a smartphone alert about brake pad wear before you even hear a squeal. This is now possible thanks to Artificial Intelligence (AI) and the Internet of Things (IoT). Sensors embedded within the brake system collect data on pad thickness, temperature, and driving habits.

This data is then analyzed by AI algorithms to predict remaining pad life, sending personalized alerts to your phone. The system can even learn your usual routes, adjusting wear predictions based on factors like traffic and road conditions. These smart systems can also communicate with your mechanic, automatically scheduling maintenance based on predicted wear. This proactive approach minimizes downtime, ensuring optimal brake condition and simplified maintenance.

Advanced algorithms are pushing brake monitoring even further. They analyze individual driving habits—like hard braking frequency and road types—to create personalized wear profiles. This allows for significantly more accurate predictions of remaining pad life.

The system can anticipate your needs, alerting you to potential issues before they become serious. When planning for the future of brake monitoring, sustainability is also key. Consider the recyclability of brake components for environmentally conscious maintenance.

Electric vehicles (EVs) pose unique challenges for brake monitoring. Regenerative braking uses the electric motor to slow the car, reducing reliance on friction brakes and resulting in slower pad wear. Traditional wear indicators become less effective, necessitating new detection methods.

Manufacturers are developing specialized sensors and algorithms that factor in regenerative braking, accurately monitoring pad wear in EVs. This adaptation is critical for maintaining brake effectiveness in these increasingly popular vehicles.

In autonomous vehicles, continuous brake monitoring is a critical safety requirement. These vehicles rely heavily on their braking systems, making malfunctions potentially disastrous. Sophisticated sensors constantly monitor brake performance and pad wear.

The vehicle can instantly identify problems and take corrective action, like pulling over. This continuous monitoring is essential for ensuring safe and reliable self-driving operation. The future of autonomous driving hinges on the reliability and safety provided by advanced brake monitoring.

Industry experts anticipate upcoming regulations mandating advanced brake monitoring across all vehicles. These regulations could standardize features like predictive alerts and Advanced Driver-Assistance Systems (ADAS) integration. This would provide all drivers with the latest safety advancements.

Such potential regulations reflect a growing emphasis on proactive safety in the automotive industry, ensuring wider adoption of these potentially life-saving technologies.

Don’t wait for a squeal or warning light. Visit Kwik Kar of Mesquite today for a comprehensive brake inspection. Our ASE-certified technicians utilize state-of-the-art equipment to ensure peak brake condition. We offer a 24-month/24,000-mile warranty on all repairs for your peace of mind. Experience the Kwik Kar difference.